Mixing Equipment - - MAXWELL-3

Filling Line Introduce

Mayonnaise Filling Line

The target market of our brand has been continuously developed over the years. Now, we want to expand the international market and confidently push our brand to the world.

1. Bottle Sorting Machine Parameter

● Turntable diameter : 800mm

● Canning speed : 30-50 cans/minute

● Power supply : 220V, 50HZ, 0.18KW

● Overall Dimension : 1000mm W 800mm H 1200mm

● Function : Organize and arrange the bottles or cans placed manually

2. Automatic Bottle Washing Machine Parameter

● Working pressure : 0.5-0.7Mpa

● Power : 1.2kw

● Voltage : 220V

● Production capacity : 1500-1800 bottles/hour

3. Mayonnaise Filling Machine Parameter

● Filling capacity : 1000-5000ml (can be customized)

● Filling speed : 20-25 bottles / min

● Voltage : 380V

● Motor power : 2KW

● Air consumption(MIN) : 4KGS×30LITER

● Air pressure : 0.6-0.8mpa

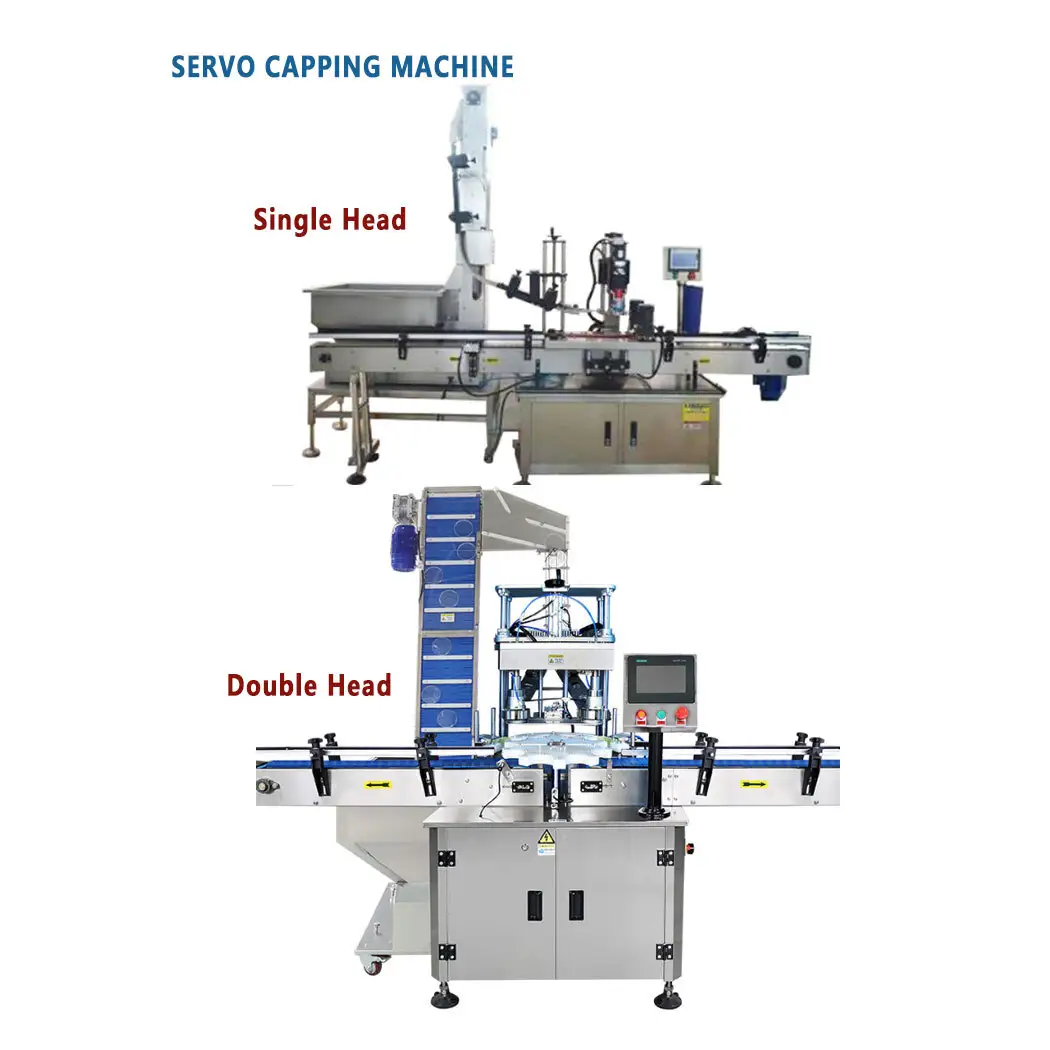

4. Servo Capping Machine Parameter

● Power supply voltage : AC 220V/50HZ

● Power : 1500W

● Adaptable cap diameter : within 100mm (can be customized)

● Working air pressure : 0.5-0.7mpa

● Production capacity : 15-30 bottles/minute

5. Round Bottle Labeling Machine Parameter

● Power supply voltage : AC 220V/50HZ

● Power : 1200W

● Applicable product range : outside diameter 30-100mm height 30-200mm

● Applicable labeling range : height 15-130mm

● Production capacity : 25-50 bottles/minute

5-2. Bottle Neck Labeling Machine (including shrink machine)

Parameter

● Registering speed : around 0-120P/min

(depending on the size of the product and label)

● Marking accuracy : ±1mm (excluding product labeling and other errors)

● Applicable product size : Diameter φ25mm~φ110mm

Height 30mm~280mm

● Applicable label range : Length 20~260mm

● Maximum label supply : Outer diameter 500mm

Inner diameter 76mm

● Ambient Temperature : 0-50℃

● Humidity : 15-85%

● Voltage specification : AC220/380V, 50HZ

● Width : 5000mm

● Height : 2000mm

● Weight : around 300KG

Application

Widely used in: Salad Dressing, Custard Dressing, Cheese, Dressing, Mayonnaise, Costa Sauce, Pastry Sauce, Baked Rock Sauce, Mustard Sauce ,Cheese sauce, Ketchup, Chocolate, Pet Nutrition Cream, etc.

Company Advantages

· MAXWELL mixing equipment is manufactured using the best quality raw material and cutting edge technology under the guidance of skilled professionals. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

· The product performance is fine, the quality is stable and reliable. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

· Wuxi MAXWELL Automation Technology Co., Ltd has set up an integrated sales network in domestic market. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

Company Features

· As one of the most fantastic mixing equipment manufacturers, MAXWELL stands out on the market.

· The quality of mixing equipment is strictly controlled by our QC team.

· We are committed to annual donations to the local construction of a school or medical center. We are working hard to benefit more people from our social caring projects.

Application of the Product

Our mixing equipment is widely used in various scenarios.

With a focus on customers' potential needs, MAXWELL provides customers with one-stop solutions.