Vacuum Emulsifying Mixer Machine by MAXWELL-3

Product details of the vacuum emulsifying mixer machine

Quick Overview

Various sizes and colors are available for our vacuum emulsifying mixer machine. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea Excellent performance: the product is superior in performance, which could be seen in the test reports and the users' comments. This makes it highly cost-effective and widely recognized. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea Wuxi MAXWELL Automation Technology Co., Ltd has been sprung up as the preferred brand for vacuum emulsifying mixer machine. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

Product Introduction

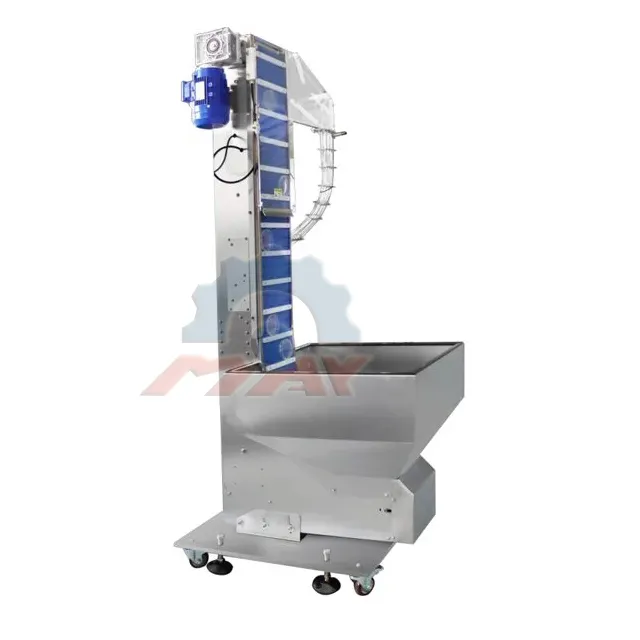

Compared with similar products, our company's vacuum emulsifying mixer machine has the following outstanding features.

Product Introduce

Video Display

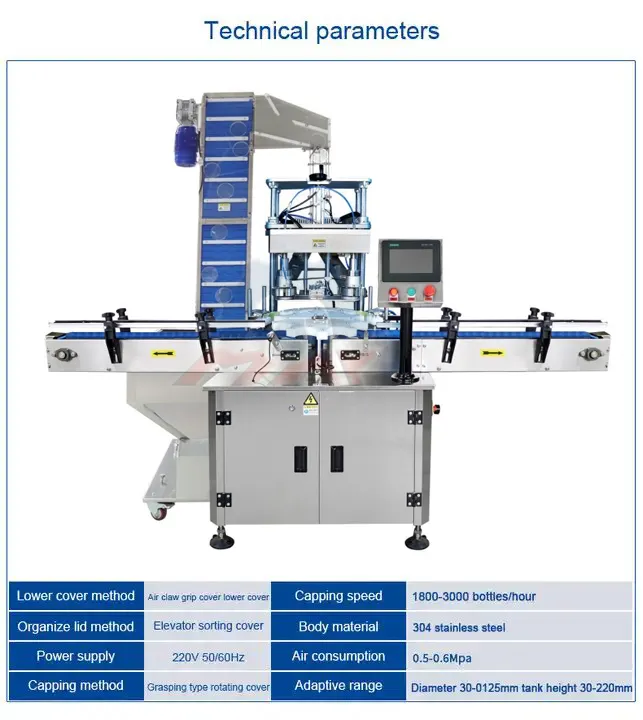

Machine Parameters

|

Type |

MAX-PLF-170 |

|

Capping speed |

1800-3000 bottle/hour |

|

Power supply |

220V |

|

Bottle height |

30-220mm (adjustable) |

|

Bottle diameter |

30-125mm (adjustable) |

|

Weight |

300kg |

|

Size |

3100 * 1082 *1940mm (L*W*H) |

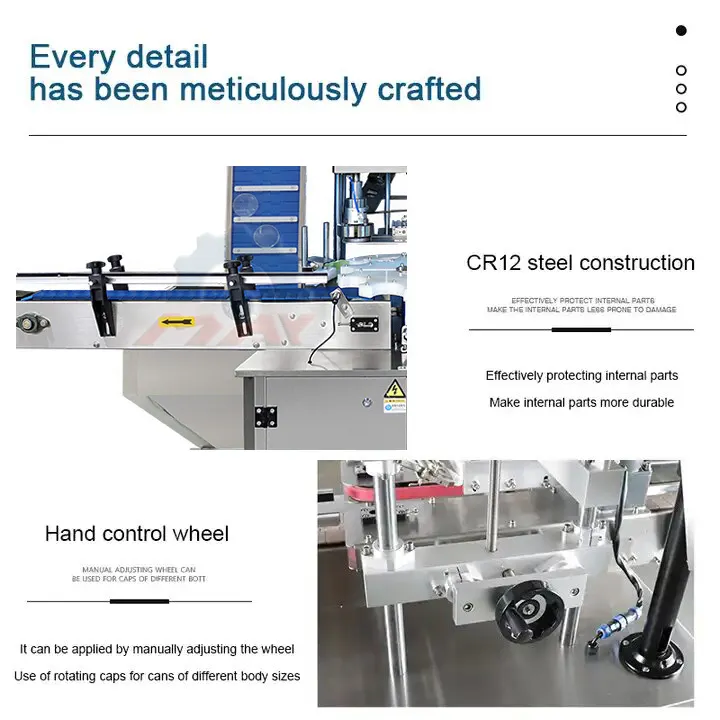

Product Features

Application

Suitable for different sizes of bottle caps

Company Information

Wuxi MAXWELL Automation Technology Co., Ltd is a company that specializes in providing customers with cosmetic makingm machine,mayonnaise making machine,vacuum emulsifying mixer,double planetary mixer,filling machine,glue filling machine,silicone sealant filling machine,vacuum planetary mixer,industrial mixer,homogenizer,lab planetary mixer,vacuum homogenizer mixer,cosmetic cream mixer machine. With a focus on integrity and quality, MAXWELL strives for excellence in the business operation. We wholeheartedly open up new fields and develop new products. We also strive to provide quality services, so as to promote the industry to develop. Our company now has a team of first-rate talents who contribute to the research and development and production of our products. MAXWELL insists on providing customers with reasonable solutions according to their actual needs.

We sincerely welcome customers with needs to contact us and cooperate with us!