Vacuum Emulsifying Mixer Machine - - MAXWELL-2

Company Advantages

· Strong R&D capability: MAXWELL vacuum emulsifying mixer machine is carefully developed by a team of dedicated professionals. In addition to that, a lot of money has been invested to improve the R&D strength. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

· Our concentrations on the design of vacuum emulsifying mixer machine has worked out finally. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

· This product will have a high retention of market share in the next few years. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

Product Introduce

Video Display

Machine Parameters

|

Model |

GSF-6 |

|

Filling range |

100-1000ml (Customizable) |

|

Filling speed |

20-35 bottles/min (Base on 100-500ml) (Also depend on filling material) |

|

Measurement accuracy |

±1% |

|

Power voltage |

2.5kw |

|

Working air pressure |

6-7kg/cm² |

|

Gas consumption |

0.7-0.9m³/min |

|

Dimention(L*W*H) |

2m*1m*2.2m |

|

Net weight |

650kg |

Features

● Adopts world-famous brands of electrical and pneumatic components, lowfailure rate, reliable performance, long service life.

● Material contact parts are made of stainless steel, easy to disassemble and assemble, easy to clean and meet the requirements of GMP.

● Easy to adjust filling volume and filling speed, operated and displayed by touch screen, beautiful appearance.

● With no bottle no filling function, liquid level automatic contral feeding.

● No need to change parts, you can quickly adjust the various specifications of the shape of the bottle.

● The filling head is equipped with a special leak-proof device. No wire drawingor drip leakage occurs during filling.

Machine Details

1. Anti-Foaming Filling Nozzle: With servo motor diving filling system to achieve the defoaming filling function, and anti-dripping with mechanical cutting and air blowing design to avoid dripping or leakage. This design enable the machine to fill thick, thin, easy foaming and many kinds of products.

2. High Precision Piston: Each stainless steel piston is polished from inside and outside, and 3mm thicker than regular piston. Such a workmanship will increase the cost, but the filling precision will become higher, service life longer, what's more less maintenance to do.

3. Diversified Air Cylinder Design: Latest cylinder design to achieve Staggered Filling Function, it makes the filling speed 1.5 times faster than traditional design. All air cylinder will be adopted with international brand, such as Festo, Air TAC.

4. Siemens PLC Touch Screen Smart Control: The filling speed and volume of each nozzle can be adjusted on the screen independently. For filling different products we can save the parameter in the screen as recipe, and one-button start when changing different packaging or products.

5. Servo Motor Control: Servo motor control makes the filling precision better, and diving filling system more smooth. Also it would be much more convenient to change filling volume and height of filling nozzle.

6. Electrical Cabinet: All the main parts of the machine will be adopted with international brand, such as Siemens, Schneider, Sick, Panasonic, etc. Long service life, easier to maintain and replace.

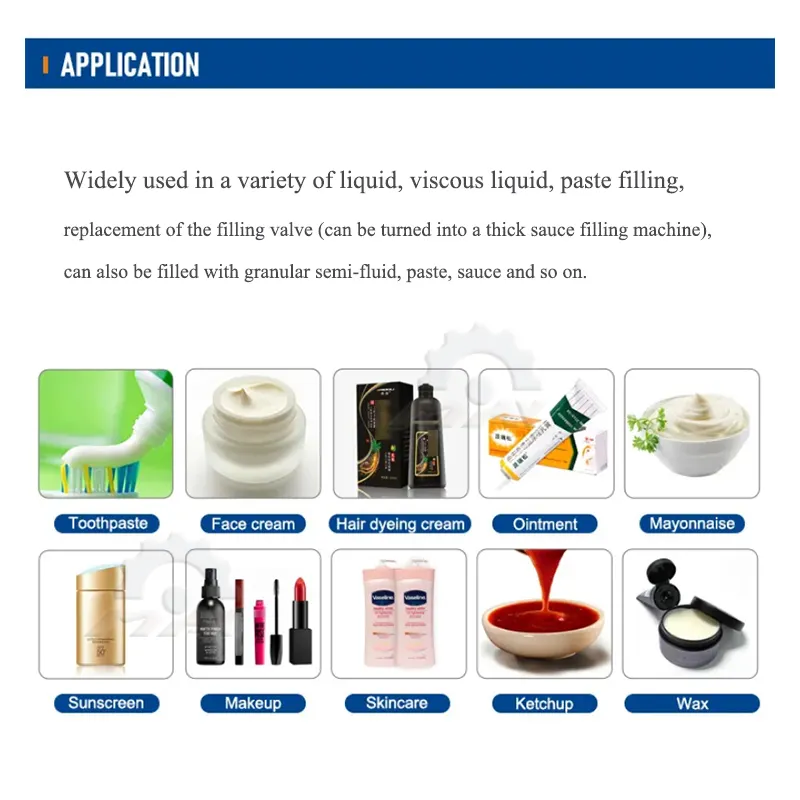

Application

Widely used in the filling of liquids, various liquids and pastes, replacement of filling valves ( that is multi-head thick sauce full-automatic filling machine), can also be filled with granular semi-fluid, paste, sauce.etc.

Company Features

· Relying on manufacturing professionalism and experience on vacuum emulsifying mixer machine, Wuxi MAXWELL Automation Technology Co., Ltd is a company highly respected in the market.

· We currently have various kinds of advanced production facilities, all of which were purchased new. Each machine is equipped with a variety of custom built setup and work holding fixtures which helps improve our production efficiency. Our factory has been equipped with a wide range of advanced production facilities. This gives us a powerful capacity that automates tasks, streamlines workflow, and helps us quickly define and validate the form, fit, and function of our product. Apart from a strong domestic market, we also have exported most of our products such as vacuum emulsifying mixer machine to Europe, U.S.A, the Middle East, Africa, and Southeast Asia.

· Regarding customer satisfactions in the first place is very important for the development of MAXWELL. Please contact.

Product Comparison

Compared with similar products, our vacuum emulsifying mixer machine's outstanding advantages are as follows.

Enterprise Advantages

We have a group of senior teams with strong research and development capabilities, and have introduced various advanced modern production equipment, providing a strong guarantee for the company's development.

Our professional service team includes a sound after-sales service system. So we are able to solve all kinds of problems and their worries.

Looking into the future, MAXWELL will adhere to the enterprise spirit, which is, to be honest, and dedicated. Our business is focused on equality, mutual benefit, and common development. With a focus on talents cultivation, we strengthen brand building and improve core competitiveness. Our final aim is to become a modern enterprise with an excellent team, strong strength and advanced technology.

Since the establishment in MAXWELL has been focusing on the strength improvement for years. So far we have accumulated rich industry experience.

With high-quality products and good reputation, our company not only sell products domestically but also exports them to various regions abroad.