خلاط كوكبي لمعجون الأسنان الفراغي المخصص

مكان المنشأ : وشى، جيانغشو، الصين

مادة: SUS304 / SUS316

التعبئة : علبة خشبية / غلاف مطاطي

وقت التسليم : 30-40 يومًا

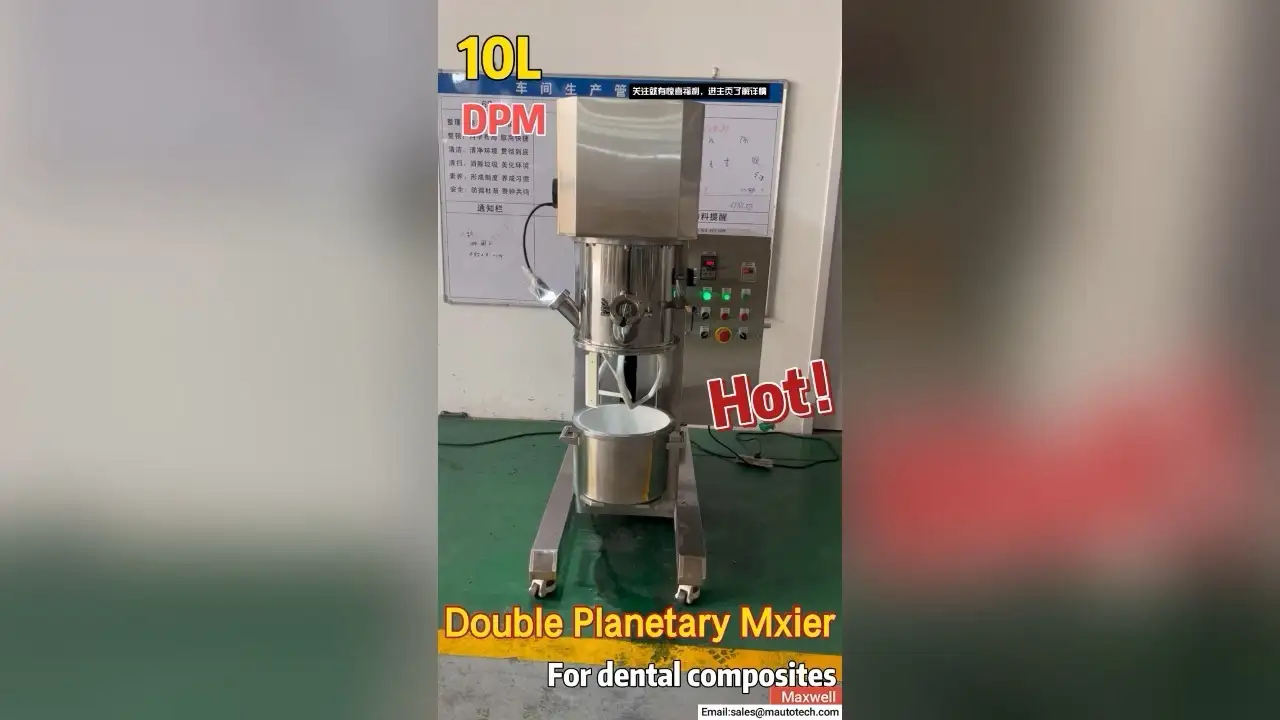

نموذج: 10L

تقديم المنتج

تُعد آلات الخلاط الكوكبي الفراغي لمعجون الأسنان المُخصص بسعة 10 لترات، الأكثر رواجًا لدى الشركات والمختبرات المتطورة التي ترغب في إنتاج كميات صغيرة باستمرار. واستجابةً للزوجة العالية لمواد طب الأسنان والحاجة إلى معدات أكثر مقاومة للتآكل، قمنا برش أوعية الخلط والمجاديف الدوارة وفقًا لمتطلبات العميل لضمان عدم تلوث المواد. وهي مناسبة لتشتيت وخلط المواد في مواد عالية اللزوجة، مثل المواد اللاصقة الهندسية، والطاقة الجديدة، ومعجون الملاط الكهربائي، والمعجون الكيميائي. كما تتوفر جميع أنواع المعاجين ذات اللزوجة الأقل من 1,000,000 سنتيبواز، ومحتوى المواد الصلبة أقل من 90%، مثل معجون بطاريات الليثيوم، ومعجون اللحام، ومعجون السيراميك، وحبر السيليكون، والمواد المانعة للتسرب، والمواد اللاصقة الهيكلية، والمراهم، ومواد الحشو المركبة، ومواد تغيير الطور، ومعجون الأسنان، وغيرها.

عرض الفيديو

معلمة المنتج

تفاصيل المنتج | 1300*800*1800 مم |

حجم عمل الخزان | 10L |

سرعة الثورة | 0~48 دورة في الدقيقة قابلة للتعديل |

سرعة دوران الخلط | 0~100 دورة في الدقيقة قابلة للتعديل |

سرعة الكاشطة | 0~48 دورة في الدقيقة قابلة للتعديل |

سرعة التشتت | 2980 دورة في الدقيقة قابلة للتعديل |

درجة الفراغ | - 0.09 ميجا باسكال |

مبدأ العمل

خلاط الطاقة الكوكبي هو نوع جديد من معدات الخلط والتحريك عالية الكفاءة، يتميز بخلوه من أي نقاط ضعف. يتميز بنظام تحريك فريد ومبتكر، مع محركين أو ثلاثة محركات، بالإضافة إلى مكشطة آلية واحدة أو اثنتين داخل الوعاء. تدور المحركات حول محور الوعاء، كما تدور حول محورها بسرعات مختلفة، لتحقيق حركات قص وعجن معقدة للمواد داخل الوعاء. كما تدور المكشطة داخل الجهاز حول محور الوعاء، لتكشط المواد الملتصقة بالجدار، مما يُسهم في الخلط وتحقيق نتائج أفضل.

يتميز الوعاء بهيكل إغلاق خاص، قادر على الخلط تحت الضغط والتفريغ، مع خصائص ممتازة لإزالة العادم والفقاعات. يمكن تسخين أو تبريد غلاف الوعاء حسب متطلبات العميل. الجهاز مُحكم الإغلاق بشكل ممتاز. يمكن رفع غطاء الوعاء وخفضه هيدروليكيًا، ويمكن تحريكه بحرية لسهولة التشغيل. علاوة على ذلك، يمكن رفع المُحركين والكاشطات مع العارضة وفصلهما تمامًا عن جسم الوعاء، مما يُسهّل التنظيف.

مميزات المنتج

هيكل الخلاط الكوكبي

● رأس خلط مزدوج الدوران

● رأس تشتيت عالي السرعة مزدوج الطبقة

● مكشطة

● رأس المستحلب (رأس المجانسة)

● صُممت رؤوس الخلط المركبة خصيصًا لعمليات مختلفة. شفرة المروحة الدوارة، وقرص التشتيت، وجهاز التجانس، والمكشطة اختيارية.

ميزتنا

في مجال تطبيق الخلاط متعدد الوظائف، اكتسبنا ثروة من الخبرة.

تشمل منتجاتنا مزيجًا من السرعة العالية والمنخفضة، والمنخفضة والمنخفضة. ينقسم الجزء عالي السرعة إلى جهاز استحلاب قص عالي، وجهاز تشتيت عالي السرعة، وجهاز دفع عالي السرعة، وجهاز تحريك فراشة. أما الجزء منخفض السرعة، فينقسم إلى تحريك مرساة، وتحريك مجداف، وتحريك حلزوني، وتحريك شريطي حلزوني، وتحريك مستطيل، وغيرها. لكل تركيبة تأثير خلط فريد، كما أنها مزودة بخاصية التفريغ والتسخين ووظيفة فحص درجة الحرارة.

وصف المنتج

1. نظام الرفع: تعمل طاولة الرفع الكهربائية أو الهيدروليكية على تحريك خزان الخلط لإغلاقه وتحريكه. مع خزانات خلط متعددة، يمكن تعديل الوصفة في أي وقت، وهي مناسبة لمختلف المختبرات والشركات الناشئة.

2. المحرك الحلزوني، لوحة التشتت، عصا درجة الحرارة، مكشطة، الخ. : يمكن تكوين أنواع مختلفة وفقا لمتطلبات العملاء.

3. خزان خلط متحرك : تصميم بمقبض مزدوج، اتجاه منفذ التفريغ مخصص، سهل الاستخدام.

4. نظام التحكم - أزرار أو PLC: يوجد مرحل زمني رقمي، يُضبط سرعة ووقت عمل الخلاط وفقًا لعملية وخصائص المنتجات المختلفة. زر طوارئ. تُدمج خزانة التحكم الكهربائية جميع وظائف التشغيل والإيقاف والتحكم والجهد والتيار وسرعة تحويل التردد للآلة، مما يُتيح ضبط وقت الخلط بشكل مركزي، مما يجعل التشغيل واضحًا ومباشرًا.

٥. مكبس هيدروليكي اختياري (آلة بثق): المكبس الهيدروليكي هو الجهاز الداعم للخلاط الكوكبي أو الموزع القوي. وظيفته تفريغ أو فصل المطاط عالي اللزوجة الناتج عن الخلاط. في آلات الخلط الكوكبية المختبرية، يمكن فصل أو دمج معدات المكبس مع خلط وكبس المواد.

طلب

مواصفات المنتج

| يكتب | تصميم مقدار | عمل مقدار | حجم الخزان الداخلي | دوار قوة | سرعة الثورة | سرعة الدوران الذاتي | قوة التشتيت | موزع سرعة | الحياة | البعد |

| SXJ-2 | 3 | 2 | 180*120 | 0.75 | 0-51 | 0-112 | 0.75 | 0-2980 | كهربائي | 800*580*1200 |

| SXJ-5 | 7.4 | 5 | 250*150 | 1.1 | 0-51 | 0-112 | 1.1 | 0-2980 | 1200*700*1800 | |

| SXJ-10 | 14 | 10 | 300*200 | 1.5 | 0-48 | 0-100 | 1.5 | 0-2980 | 1300*800*1800 | |

| SXJ-15 | 24 | 15 | 350*210 | 2.2 | 0-43 | 0-99 | 2.2 | 0-2980 | 1500*800*1900 | |

| SXJ-30 | 43 | 30 | 400*350 | 3 | 0-42 | 0-97 | 3 | 0-2980 | 1620*900*1910 | |

| SXJ-50 | 68 | 48 | 500*350 | 4 | 0-39 | 0-85 | 4 | 0-2100 | هيدروليكي | |

| SXJ-60 | 90 | 60 | 550*380 | 5.5 | 0-37 | 0-75 | 5.5 | 0-2100 | 1800*1100*2450 | |

| SXJ-100 | 149 | 100 | 650*450 | 7.5 | 0-37 | 0-75 | 11 | 0-2100 | 2200*1300*2500 | |

| SXJ-200 | 268 | 200 | 750*600 | 15 | 0-30 | 0-61 | 22 | 0-1450 | 2400*1600*2800 | |

| SXJ-300 | 376 | 300 | 850*650 | 22 | 0-28 | 0-56 | 30 | 0-1450 | 3300*1300*3400 | |

| SXJ-500 | 650 | 500 | 1000*830 | 37 | 0-24 | 0-48 | 45 | 0-1450 | 3700*1500*3500 | |

| SXJ1000 | 1327 | 1000 | 1300*1000 | 45 | 0-20 | 0-36 | 55 | 0-1450 | 4200*1800*3780 | |

| SXJ2000 | 2300 | 2000 | 1500*1300 | 75 | 0-13 | 0-35 | 90 | 0-1450 | 4500*2010*4000 |