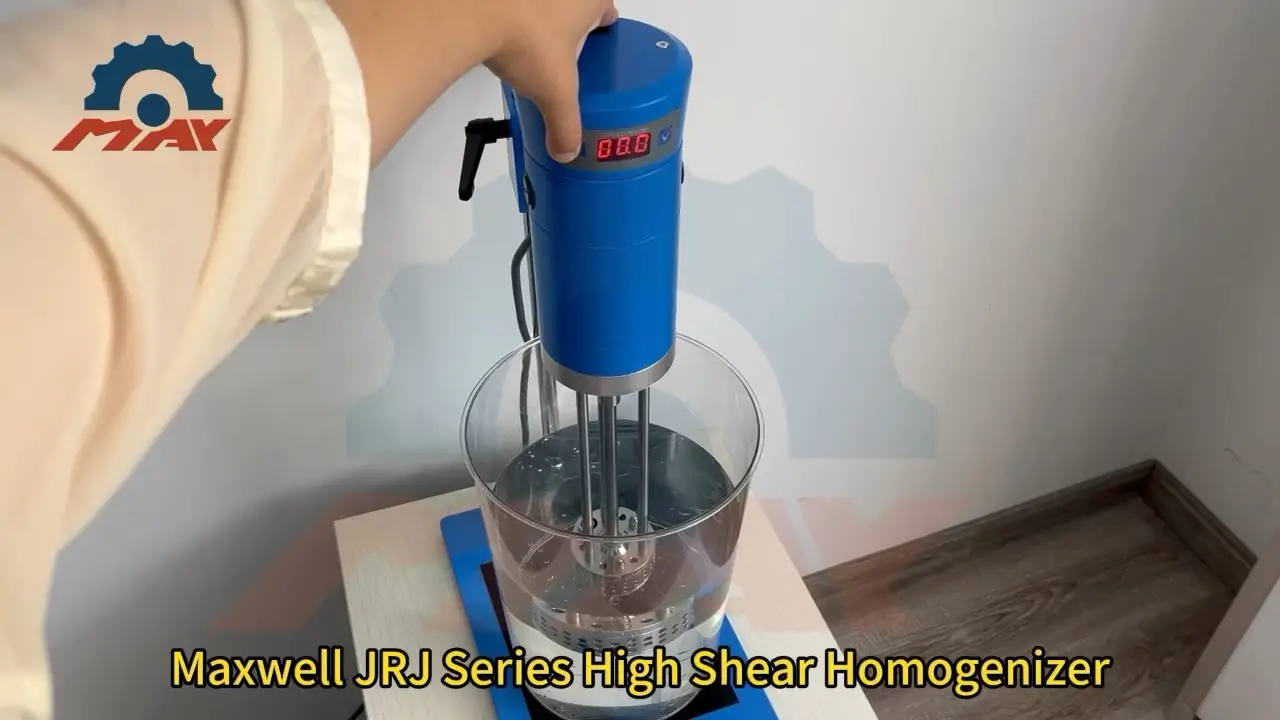

JRJ300 Benchtop Rotor Stator Homogenizer

Material: SUS304 / SUS316

Model: JRJ300-SH-BL

Capacity: 1000-40000ml

Speed: 200-11000rpm

Stator type: Ø 5mm², Ø 20mm², Ø 50mm²

Working head: Ø 70mm

Max Viscosity: 12000Mpas

Product Introduce

Video Display

Product Parameters

|

Working head |

JRJ300-SH |

|

Speed(rpm) |

200-11000rpm |

|

Capacity |

1000-40000ml |

|

Input power |

510W |

| Dimension | 250*650*720mm |

|

Working head |

Ø 70mm |

|

Stator type |

Ø 5mm², Ø 20mm², Ø 50mm² |

|

Torque |

34.1N.cm |

|

Max Viscosity |

12000Mpas |

|

Working way |

interrupted |

|

Power |

AC 220V 50HZ |

Product Features

Application

Mixing: syrups, shampoos, washing liquids, juice concentrates, yogurt, desserts, mixed dairy products, oil allies, enamel dispersion mixing: methyl cellulose dissolution, colloid dissolution, carbide dissolution, oil-water emulsification, pre-mixing, seasoning production, stabilizers dissolution, soot, salt, alumina, pesticides, etc.

Dispersing: suspensions, pill coating, drug depolymerization, paint dispersion, lip balm, vegetable bouillon, mustard mixtures, catalysts, matting agents, metals, pigments, modified asphalt, preparation and depolymerization of nanomaterials, etc.

Emulsification:Pharmaceutical emulsions, ointments, creams, masks, face creams, emulsified flavors, oil-water emulsions, emulsified asphalt, resin emulsions, wax emulsions water-based polyurethane emulsions, pesticides, etc.

Homogenization: pharmaceutical emulsions, ointments, creams, masks, creams, tissue homogenization, dairy homogenization, fruit juices, printing allied water, jams, etc.

Mixer for tinned food, drinks, cosmetics, reagent, oil, bath shampoo, ointment, toothpaste, oil, perfume, beverage,coating, adhesive, etc.

Application Scenario