Cosmetic Cream Mixers - - MAXWELL

Product details of the cosmetic cream mixers

Quick Detail

The production process of MAXWELL cosmetic cream mixers is smooth and high-efficiency. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea The superior material makes the product superb in quality. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea With its considerable prospects, this product is worth expanding and promoting. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

Product Introduction

MAXWELL's cosmetic cream mixers has excellent performances by virtue of the following excellent details.

Product Introduce

Realize the process of material dispersion, emulsification, homogenization and mixing under vacuum or pressure environment. It can be equipped with a variety of high-viscosity stirrers, high-shear homogenizers, and reliable vacuum sealing systems and temperature control systems. Various sensing and detection systems can simulate industrial production in a laboratory environment.

At present, the laboratory processing capacity is: 1L, 2L and other series. It is used for dispersion, mixing, emulsification, homogenization, stirring and dissolving in the laboratory. The whole reaction process of stirring, homogenizing, emulsifying, dispersing, mixing, etc. of the material can be observed through a glass kettle under vacuum or pressure conditions, and it can also be homogeneously emulsified and dispersed by stainless steel pressure and high temperature.

Video Display

Working Principle

Put the materials into premix tank oil phase tank and water phase tank,after heated & mixed in water tank and oil tank, it can drawn the materials into emulsifying tank by vacuum pump. Adopting the middle stirrer & Teflon scrapers residues in emulsifying tank that sweep the residues on the wall of the tank to makes the materials wiped off become the new interface constantly.

Then the materials will cut off, compressed and fold by the blades to stir, mix and run to the homogenizer. By the strong cutting off, impact and turbulent current from the high-speed shear wheel and fixed cutting case, the materials are cut off in interstices of stator and rotor and turn to particles of 6nm-2um promptly. Because the emulsifying tank is working under the vacuum state, the bubbles that produces in the process of mixing is taken away in time.

Product Features

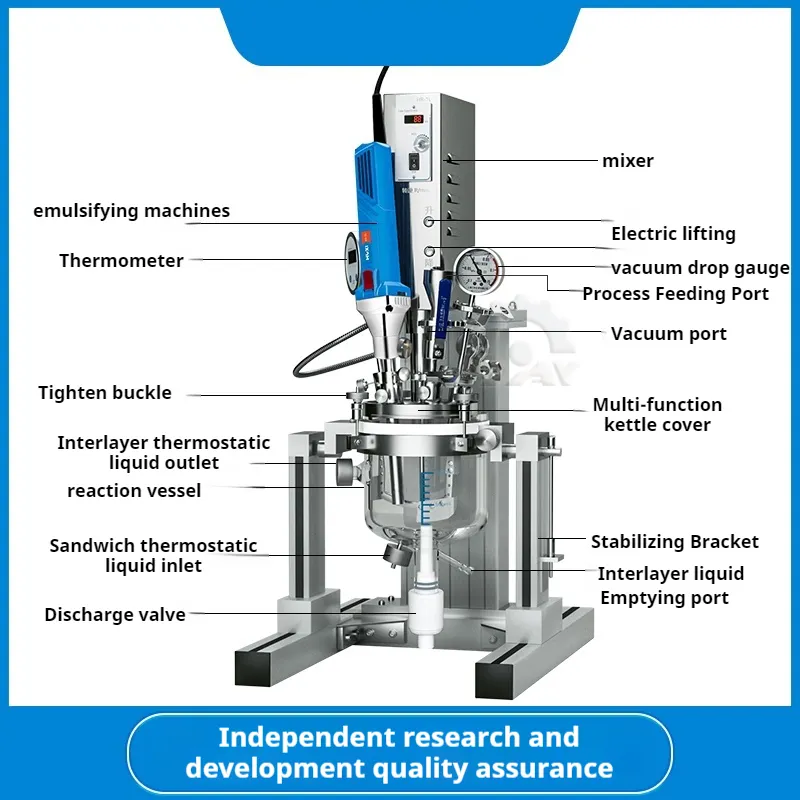

Emulsifying machine structure diagram

Product Description

Application

Company Advantages

Wuxi MAXWELL Automation Technology Co., Ltd is a industrialized management company, and currently the main product is cosmetic makingm machine,mayonnaise making machine,vacuum emulsifying mixer,double planetary mixer,filling machine,cosmetics filling machine,labelling machine. With the vision of 'sustainable development' and the mission of 'continuously creating value for customers and promoting change', our company is committed to growing into the world's most influential enterprise with brand value. Our huge production line personnel base lays a firm foundation for the production and processing of products; professional technicians provide technical guarantee for the quality and safety of products; high-quality management personnel increase the momentum for enterprise development with humanistic and scientific management. In addition to creating excellent cosmetic makingm machine,mayonnaise making machine,vacuum emulsifying mixer,double planetary mixer,filling machine,cosmetics filling machine,labelling machine, MAXWELL is also able to provide comprehensive and reasonable solutions for customers.

Our products are of high quality and great safety. Besides, they are packed tightly and shockproof. Customers can rest assured to purchase our products and are warmly welcomed to contact us for details.