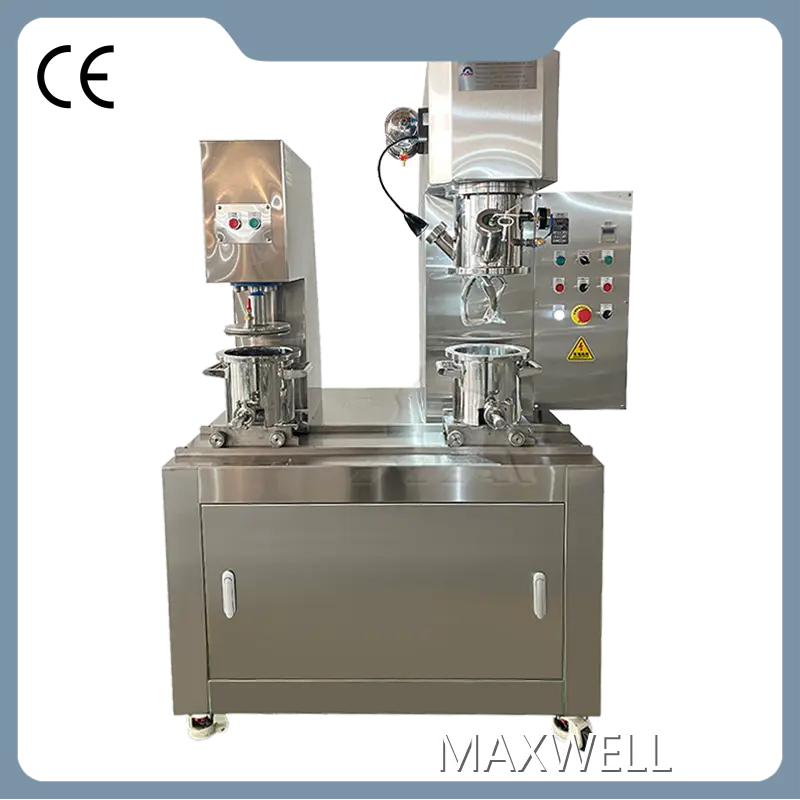

Industrial Mixer Blender - - MAXWELL

Product Introduce

The double planetary mixer adopted advanced technology, which is widely used in dispersing mixing middle or high viscosity liquid-liquid/solid-solid/liquid-solid material, such as adhesives, sealant, silicone rubber, glass glue, solder paste, quartz sand,battery paste, electronic slurry, lithium battery slurry, polyurethane, coating, pigment, dyestuff, synthetic resin rubber,ointment and etc for for electronics, chemical,construction and agricultural industries. Which the viscosity is app. from 5000cp to 1000000cp.

Video Display

Working Principle

Planetary power mixer is a kind of new high-efficiency mixing and stirring equipment with no dead spot. It features unique and novel stirrer mode, with two or three stirrers as well as one or two auto scrapers inside the vessel. While revolving around the axle of the vessel, the stirrers also rotate around its own axis at different speeds, to achieve complicated movement of strong shearing and kneading for materials inside the vessel. Besides, the scraper inside the equipment revolves around the axle of the vessel, scraping the materials adhering to the wall for mixing and achieving better effects.

The vessel adopts special sealing structure, capable of pressurized and vacuumized mixing, with excellent exhaust and bubble removal effects. Vessel jacket can be heating or cooling according customer's requirements. The equipment is sealed excellently. The vessel cover can be hydraulically lifted and lowered, and vessel can be moved freely for ease of operation. Furthermore, the stirrers and scraper can rise with the beam and fully detach from vessel body, for ease of cleaning.

Machine Features

Planetary Mixer Structure

● Double Twist Mixing Head

● Double-layer high speed dispersing head

● Scraper

● Emulsifying head ( Homogenizer head )

● The mixing head combination forms are tailored for different process. Twist impeller blade, Dispersing disc, Homogenizer and Scraper are optional.

Product Details

In the application field of the multi-function mixer, we accumulated a wealth of experience. Our product combination include the combination of high speed and high-speed, the combination of high-speed and low-speed and the combination of low-speed and low-speed. High-speed part is divided into high shear emulsification device, high-speed dispersion device, high-speed propulsion device, butterfly stirring device. Low-speed part is divided into anchor stirring, paddle stirring, spiral stirring, helical ribbon stirring, rectangular stirring and so on. Any combination has its unique mixing effect. It also have vacuum and heating function and temperature inspect function.

Machine Details Description

1. Electric lifting tank: The electric lifting function of the tank can effectively stir the materials under closed conditions. It is easy to clean in the pot and easy to operate.

2. Spiral stirrer, scraper, dispersion plate: Various types can be configured according to customer requirements

3. Control system: There is a digital time relay, which can adjust the speed and working time of the mixer according to the process and characteristics of different products. emergency button. The electrical control cabinet integrates all the power on, off, control,voltage, current, and frequency conversion speed of the machine, and the mixing time setting is reasonably centralized,and the operation is clear at a glance

4. Extruder (Press machine): The press machine is the supporting equipment of the planetary mixer or the powerful disperser. Its function is to discharge or separate the high-viscosity rubber produced by the mixer.For laboratory planetary mixing machines,the press equipment can be integrated with mixing and pressing of the material.

Our advantage

In the application field of the multi-function mixer, we accumulated a wealth of experience.

Our product combination include the combination of high speed and high-speed, the combination of high-speed and low-speed and the combination of low-speed and low-speed. High-speed part is divided into high shear emulsification device, high-speed dispersion device, high-speed propulsion device, butterfly stirring device. Low-speed part is divided into anchor stirring, paddle stirring, spiral stirring, helical ribbon stirring, rectangular stirring and so on. Any combination has its unique mixing effect. It also have vacuum and heating function and temperature inspect function

Application

Product Specification

| Type | Designvolume | Workingvolume | Tank inner size | Rotarypower | Revolution speed | Self-rotary speed | Disperser power | Disperserspeed | Lifing | Dimension |

| SXJ2 | 3 | 2 | 180*120 | 0.75 | 0-51 | 0-112 | 0.75 | 0-2980 | Electric | 800*580*1200 |

| SXJ5 | 7.4 | 5 | 250*150 | 1.1 | 0-51 | 0-112 | 1.1 | 0-2980 | 1200*700*1800 | |

| SX110 | 14 | 10 | 300*200 | 1.5 | 0-48 | 0-100 | 1.5 | 0-2980 | 1300*800*1800 | |

| SXJ15 | 24 | 15 | 350*210 | 2.2 | 0-43 | 0-99 | 2.2 | 0-2980 | 1500*800*1900 | |

| SXJ30 | 43 | 30 | 400*350 | 3 | 0-42 | 0-97 | 3 | 0-2980 | 1620*900*1910 | |

| SXJ50 | 68 | 48 | 500*350 | 4 | 0-39 | 0-85 | 4 | 0-2100 | Hydraulic | |

| SXJ60 | 90 | 60 | 550*380 | 5.5 | 0-37 | 0-75 | 5.5 | 0-2100 | 1800*1100*2450 | |

| SX1100 | 149 | 100 | 650*450 | 7.5 | 0-37 | 0-75 | 11 | 0-2100 | 2200*1300*2500 | |

| SX1200 | 268 | 200 | 750*600 | 15 | 0-30 | 0-61 | 22 | 0-1450 | 2400*1600*2800 | |

| SX1300 | 376 | 300 | 850*650 | 22 | 0-28 | 0-56 | 30 | 0-1450 | 3300*1300*3400 | |

| SXJ500 | 650 | 500 | 1000*830 | 37 | 0-24 | 0-48 | 45 | 0-1450 | 3700*1500*3500 | |

| SXJ1000 | 1327 | 1000 | 1300*1000 | 45 | 0-20 | 0-36 | 55 | 0-1450 | 4200*1800*3780 | |

| SXJ2000 | 2300 | 2000 | 1500*1300 | 75 | 0-13 | 0-35 | 90 | 0-1450 | 4500*2010*4000 |

Company Advantages

· The design of MAXWELL industrial mixer blender adopts advanced concept that exceeds the market. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

· A series of strict pre-delivery testing is carried out to eliminate the defect product. The testing is strictly conducted by our testing personnel and thus the quality of this product can be guaranteed. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

· Fast and personalized service are guaranteed in Wuxi MAXWELL Automation Technology Co., Ltd. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

Company Features

· Wuxi MAXWELL Automation Technology Co., Ltd is recognized as the industry's first brand of Chinese industrial mixer blender.

· Over the years, we have won various titles, such as honor of China's Influential Enterprise and High-Integrity Enterprise. These awards are strong evidence of our manufacturing and supplying competence.

· Sustainability is at the heart of our business. Our operation focus on waste reduction, resource efficiency, sustainability innovation, and ecological sourcing.

Application of the Product

industrial mixer blender developed and produced by our company can be widely used in various industries and professional fields.

MAXWELL always provides customers with reasonable and efficient one-stop solutions based on the professional attitude.