Mayonnaise Emulsifier - - MAXWELL

Product details of the mayonnaise emulsifier

Product Description

mayonnaise emulsifier looks great with our professional design and delicate shape. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea Its service life and performance are greatly optimized and improved. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea The popularity of this product among customers is increasing and has no sign of slow down. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

Product Introduce

The Semi-auto filling and capping machine is powered by Gear wheel pump, The glue is extracted from two buckets and filled into a small two-component cartridge, And the extension tube is extended into the bottom of the cartridge to fill the fluid with uniform motion, Which can prevent air from entering the material, When the sensor detects that the material reaches the capacity, It will immediately stop working to ensure the accuracy of the capacity.

At the same time, On the other side of the machine, The pistons can be pressed into the cartridge,A machine for two purposes, And only one person to operate, It is greatly improving the work efficiency.

It can filling into 25ml 50ml 75ml 200ml 400ml 600ml 250ml 490ml Two component Cartridges, Ratio:1:1 2:1 10:1 4:1, Please let me know your requirements.

Video Display

Product Parameter

|

Type |

MAX-F001 |

|

Pressure Barrel |

15L \ 30L Adjustable |

|

Power Supply |

220V / 50HZ |

|

Working air pressure |

0.4~0.7 MPa |

|

Filling Volume |

25ml 50ml 75ml 200ml 400ml 600ml adjustable |

|

Volume Precision |

±1~2% |

|

Speed |

120~600pcs/hour |

|

Dimensions(L×W×H) |

1200mm×1000mm*1600mm |

|

Weight |

Around 300kg |

Product Advantage

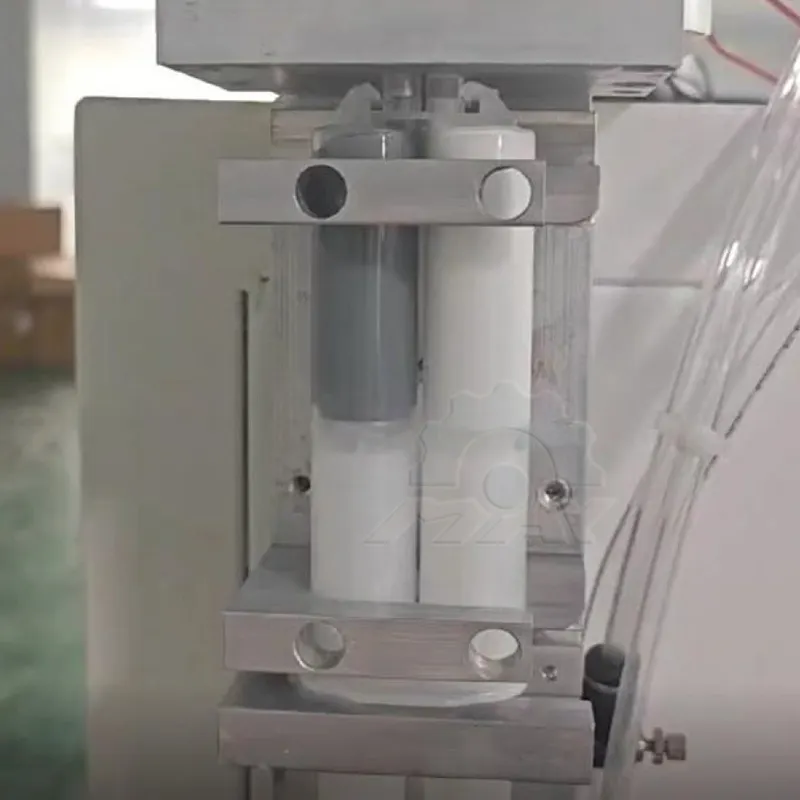

Dual Cartridge Filling Machine Structure

● ① Outlet valve

● ② Emergency stop button

● ③ Glue filling button

● ④ Fixture of AB cartridge

● ⑤ Glue quantity sensor

● ⑥ Glue sensor fixing screw

● ⑦ Pistion depth adjustment screw

● Press down piston button, Press down piston structure, Glue outlet tube, Touch screen,etc.

Application

This machine is suitable for AB adhesive, epoxy resin, polyurethane adhesive, PU adhesive, acrylic rubber, rock board adhesive, silicone, thixotropic silicone, sealant, planting glue, casting glue, silica gel, etc.

Factory advantage

In the application field of the multi-function mixer, we accumulated a wealth of experience.

Our product combination include the combination of high speed and high-speed, the combination of high-speed and low-speed and the combination of low-speed and low-speed. High-speed part is divided into high shear emulsification device, high-speed dispersion device, high-speed propulsion device, butterfly stirring device. Low-speed part is divided into anchor stirring, paddle stirring, spiral stirring, helical ribbon stirring, rectangular stirring and so on. Any combination has its unique mixing effect. It also have vacuum and heating function and temperature inspect function

Company Feature

• MAXWELL was incorporated in After years of unremitting exploration, we successfully develop the business in consideration of our own conditions.

• MAXWELL has a group of experienced personnel and maintains long-term cooperation with famous domestic scientific research institutions. This provides favorable conditions for corporate development.

• MAXWELL is able to provide professional and thoughtful services for consumers for we have various service outlets in the country.

• At the moment, our company's sales network has spread all over the country's major cities and regions. In the future, we will strive to open up a broader overseas market.

If you are looking for quality products and professional services, please contact MAXWELL.