Semi Automatic Low Viscosity AB Glue Filling Machine Glue Dispensing Machine

Model: MAX-F005

Pressure Barrel: 30 L, adjustable

Power Supply: 220V / 50Hz

Voltage: 220V, 110V, 380V (customizable)

Working Air Pressure: 0.4–0.7 MPa

Filling Volume: 25ml 50ml 75ml 200ml 400ml 600ml 250ml 490ml 850ml, adjustable

Ratio: 1 : 1 , 2 : 1 , 4 : 1 , 10 : 1

Volume Precision: ±1%

Speed: 300–900 pcs/hr

Dimensions: 1100mm × 900mm × 1600mm

Weight: Around 300 kg

Product Introduce

The Maxwell MAX-F005 Semi Automatic Low-Viscosity AB Glue Filling Machine is built for precise dispensing of low-viscosity adhesives such as epoxy, PU and acrylic. With adjustable filling volumes from 50ml to 490ml and speeds up to 900 pcs/hr, it ensures ±1% metering accuracy and smooth, bubble-free flow. Integrated A/B tanks, injection valves, and piston injectors support consistent ratio control and secure sealing. Its touch screen interface and modular design make operation simple and maintenance efficient—ideal for industrial applications requiring fast, reliable adhesive filling.

The two components ab glue filling and capping machine is powered by Gear wheel pump, The glue is extracted from two buckets and filled into a small two-component cartridge, And the extension tube is extended into the bottom of the cartridge to fill the fluid with uniform motion, Which can prevent air from entering the material, When the sensor detects that the material reaches the capacity, It will immediately stop working to ensure the accuracy of the capacity.At the same time, On the other side of the machine, The pistons can be pressed into the cartridge,A machine for two purposes, And only one person to operate, It is greatly improving the work efficiency.

More Maxwell ab two components glue/adhesive filling machine with full automatic or semi automatic, for dual cartridge or dual syringe, for low viscosity or high viscosity material, designed for filling into 25ml 50ml 75ml 200ml 400ml 600ml 250ml 490ml 825ml Two component Cartridges, Ratio: 1:1, 2:1, 4:1, 10:1. Welcome to contact us get factory price.

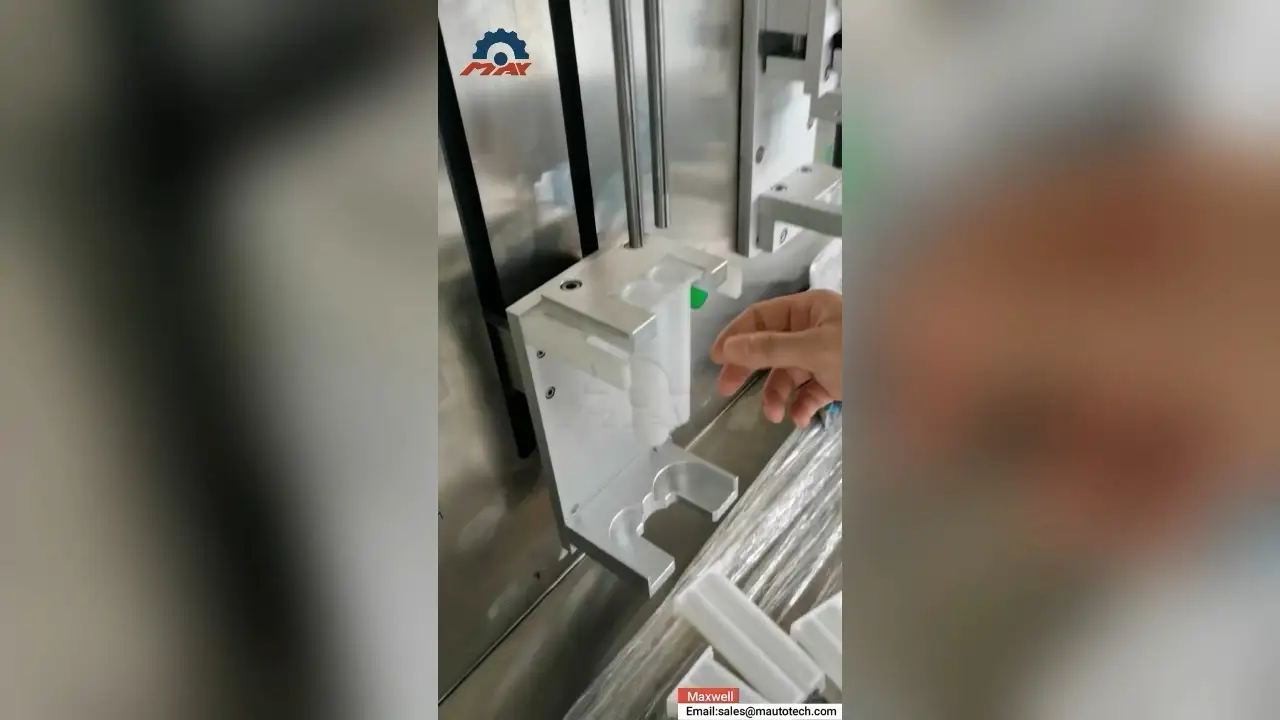

Video Display

Product Parameter

|

Type |

MAX-F005 |

|

Pressure Barrel |

30L Adjustable |

|

Power Supply |

220V / 50HZ |

|

Working air pressure |

0.4~0.7 MPa |

|

Filling Volume |

25ml 50ml 75ml 200ml 400ml 600ml adjustable |

|

Volume Precision |

±1% |

|

Speed |

300~900pcs/hour |

|

Dimensions(L×W×H) |

1100mm×900mm*1600mm |

|

Weight |

Around 300kg |

Product Advantage

Dual Cartridge Filling Machine Structure

● ① Outlet valve

● ② Emergency stop button

● ③ Glue filling button

● ④ Fixture of AB cartridge

● ⑤ Glue quantity sensor

● ⑥ Glue sensor fixing screw

● ⑦ Pistion depth adjustment screw

● Press down piston button, Press down piston structure, Glue outlet tube, Touch screen,etc.

Application

This AB glue filling machine is suitable for dispensing liquid adhesive or materials,such as AB adhesive, epoxy resin, polyurethane adhesive, PU adhesive, acrylic rubber, rock board adhesive, silicone, thixotropic silicone, sealant, planting glue, casting glue, silica gel, etc.

Factory advantage

In the application field of the multi-function mixer, we accumulated a wealth of experience.

Our product combination include the combination of high speed and high-speed, the combination of high-speed and low-speed and the combination of low-speed and low-speed. High-speed part is divided into high shear emulsification device, high-speed dispersion device, high-speed propulsion device, butterfly stirring device. Low-speed part is divided into anchor stirring, paddle stirring, spiral stirring, helical ribbon stirring, rectangular stirring and so on. Any combination has its unique mixing effect. It also have vacuum and heating function and temperature inspect function