Mixing Equipment by MAXWELL-1

Company Advantages

· MAXWELL mixing equipment is designed by our experienced designers that are leaders in the industry. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

· This product performance is superior, the service life is long, enjoys the high prestige in the international. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

· The product has gained remarkable sales in the global market and has a good market outlook. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

Product Introduce

Video Display

Product Parameter

|

Size |

3000mm×1550mm*1900mm |

|

Air Supply |

>0.5 MPa |

|

Filling Volume |

MAX 350ml Adjustable |

|

Volume Precision |

≤±0.5℅ |

|

Speed |

1200~2400pcs/hr |

|

Weight |

750kg |

Function

Product structure diagram

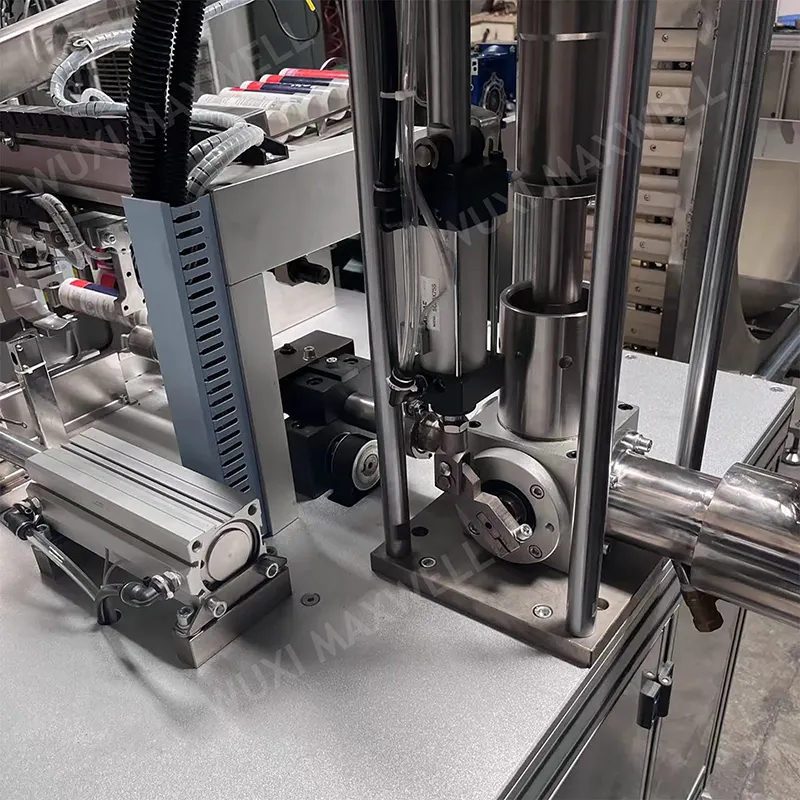

Machine Details

1. Filling & Capping system: Adopt volumetric measuring cylinder, servo motor control quantitative. Filling measurement accuracy is high (error 0.5%). No air comes in during the whole process.

2. Cartridge loading device: Adopt cartridge loader automatic loading the tube on machine. Silicone stations filling part connect with drum press and equip cartridge pushing and pulling function.

3. Cap loading device: Cap elevator and tunnel to auto load cap. Adopt vibrating bowl automatic loading cap. Air cylinder pushes cap on the tube bottom and then turn tube capping it.

4. Servo control system: Servo motor controlled filling, the whole work process is running stable.

Press Machine Parameter

|

Equipment name |

Press Material Machine |

|

Type |

YJ200-1/YJ200-2 |

|

Power Supply |

AC 3~380V+Nwire /50HZ |

|

Extrusion force |

45T/60T |

|

suitable bucket |

200L(Dia570MM*Heigh880MM) standard bucket |

|

Outlet size |

DN65 |

|

Hydraulic station oil tank |

120L |

|

motor |

4KW/Hydraulic motor |

|

Hydraulic station oil size |

L650MM*W550MM*H800MM |

Application

Company Features

· Wuxi MAXWELL Automation Technology Co., Ltd is a strategy partner for several well-known domestic and foreign mixing equipment companies.

· Our company has excellent product designers. They are always creative with inspirations driven from Google image, Pinterest, Dribbble, Behance, etc. They can create sought-after products.

· To achieve the harmonious cooperation between MAXWELL and customers is our pursuit. Get quote!

Product Details

To better learn about mixing equipment, MAXWELL will provide detailed pictures and detailed information in the following section for your reference.

Application of the Product

MAXWELL's mixing equipment can be used in different fields.

With rich manufacturing experience and strong production strength, MAXWELL is able to provide professional solutions according to customers' actual needs.

Product Comparison

MAXWELL guarantees cosmetic makingm machine,mayonnaise making machine,vacuum emulsifying mixer,double planetary mixer,filling machine,cosmetics filling machine,labelling machine to be high-quality by carrying out highly standardized production. Compared with other products in the same category, it has the following advantages.