Vacuum Emulsifying Mixer Machine by MAXWELL-1

Product details of the vacuum emulsifying mixer machine

Product Overview

The structure of MAXWELL vacuum emulsifying mixer machine is more compact so as to effectively reduce labor intensity and shorten operating time. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea A series of quality tests are conducted on the entire range to seek out any possible defect. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea The company culture Wuxi MAXWELL Automation Technology Co., Ltd sticks to is to make qualified vacuum emulsifying mixer machine products, and provide qualified services. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

Product Description

Our vacuum emulsifying mixer machine has the following advantages over similar products.

Product Introduce

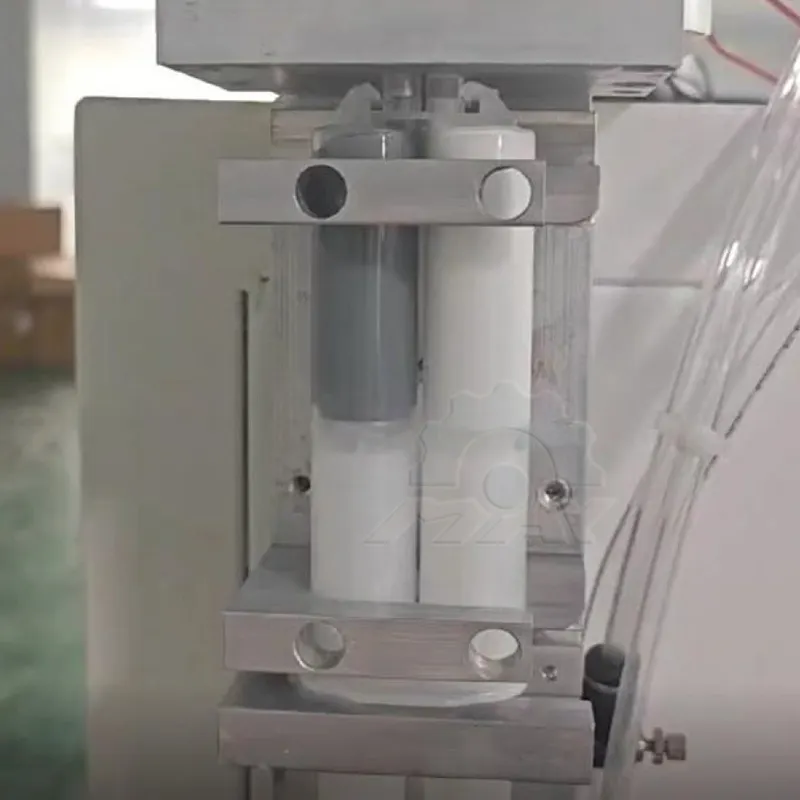

The Semi-auto filling and capping machine is powered by Gear wheel pump, The glue is extracted from two buckets and filled into a small two-component cartridge, And the extension tube is extended into the bottom of the cartridge to fill the fluid with uniform motion, Which can prevent air from entering the material, When the sensor detects that the material reaches the capacity, It will immediately stop working to ensure the accuracy of the capacity.

At the same time, On the other side of the machine, The pistons can be pressed into the cartridge,A machine for two purposes, And only one person to operate, It is greatly improving the work efficiency.

It can filling into 25ml 50ml 75ml 200ml 400ml 600ml 250ml 490ml Two component Cartridges, Ratio:1:1 2:1 10:1 4:1, Please let me know your requirements.

Video Display

Product Parameter

|

Type |

MAX-F001 |

|

Pressure Barrel |

15L \ 30L Adjustable |

|

Power Supply |

220V / 50HZ |

|

Working air pressure |

0.4~0.7 MPa |

|

Filling Volume |

25ml 50ml 75ml 200ml 400ml 600ml adjustable |

|

Volume Precision |

±1~2% |

|

Speed |

120~600pcs/hour |

|

Dimensions(L×W×H) |

1200mm×1000mm*1600mm |

|

Weight |

Around 300kg |

Product Advantage

Dual Cartridge Filling Machine Structure

● ① Outlet valve

● ② Emergency stop button

● ③ Glue filling button

● ④ Fixture of AB cartridge

● ⑤ Glue quantity sensor

● ⑥ Glue sensor fixing screw

● ⑦ Pistion depth adjustment screw

● Press down piston button, Press down piston structure, Glue outlet tube, Touch screen,etc.

Application

This machine is suitable for AB adhesive, epoxy resin, polyurethane adhesive, PU adhesive, acrylic rubber, rock board adhesive, silicone, thixotropic silicone, sealant, planting glue, casting glue, silica gel, etc.

Factory advantage

In the application field of the multi-function mixer, we accumulated a wealth of experience.

Our product combination include the combination of high speed and high-speed, the combination of high-speed and low-speed and the combination of low-speed and low-speed. High-speed part is divided into high shear emulsification device, high-speed dispersion device, high-speed propulsion device, butterfly stirring device. Low-speed part is divided into anchor stirring, paddle stirring, spiral stirring, helical ribbon stirring, rectangular stirring and so on. Any combination has its unique mixing effect. It also have vacuum and heating function and temperature inspect function

Company Advantages

As a comprehensive enterprise, Wuxi MAXWELL Automation Technology Co., Ltd integrates R&D, production, sales, import and export. We are mainly engaged in the business of cosmetic makingm machine,mayonnaise making machine,vacuum emulsifying mixer,double planetary mixer,filling machine,cosmetics filling machine,labelling machine. MAXWELL always adheres to people-oriented business. We are honest and law-abiding in the development, with the aim to gain mutual benefit. We also promote the enterprise spirit of 'compete fairly, progress actively, advance promptly'. Based on the equality and mutual benefit, we partner with other outstanding enterprises in the industry and complement with each other. Together we can further promote the industry. MAXWELL's talents are high in quality and rich in industry experience. They are the solid foundation for long-term development. MAXWELL is committed to providing customers with high-quality cosmetic makingm machine,mayonnaise making machine,vacuum emulsifying mixer,double planetary mixer,filling machine,cosmetics filling machine,labelling machine as well as one-stop, comprehensive and efficient solutions.

Our products are reliable in quality, various in type and affordable in price. Customers in need are welcomed to contact us. We sincerely hope to reach friendly cooperation, common development and mutual benefit with you!