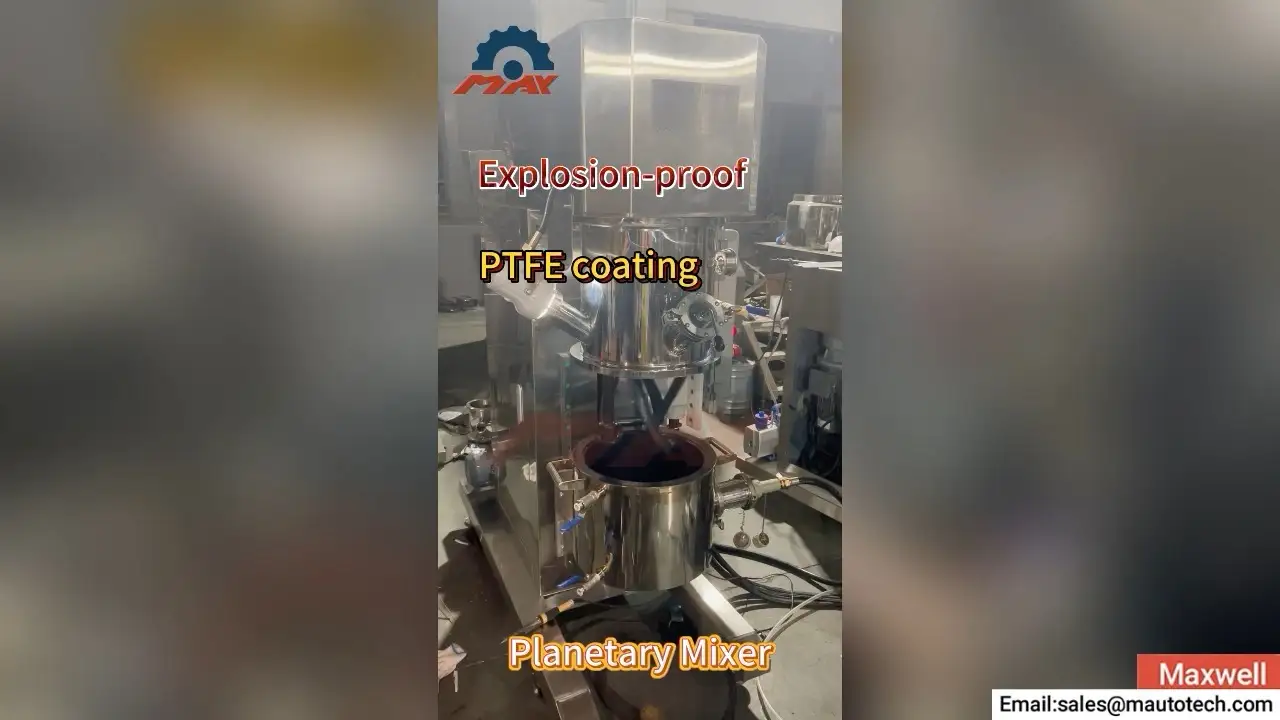

PTFE Coated Explosion Proof Lab Vacuum Planetary Mixer

Place of Origin: Wuxi,Jiangshu,China

Material: SUS304 / SUS316

Packing: Wooden Case / Stretch Wrap

Delivery time: 30-40 days

Model: 10L

PTFE Coating technology is an effective solution for addressing corrosion and erosion issues in double planetary mixers.Polytetrafluoroethylene, also known as Teflon, is a synthetic polymer material with outstanding chemical stability and high-temperature resistance. Its surface is exceptionally smooth, making it resistant to adhesion and highly corrosion-resistant, capable of withstanding the effects of various chemicals. Consequently, PTFE stir bars offer exceptional durability and stability, making them suitable for stirring operations under diverse experimental conditions.Particularly suitable for mixing and processing in the fields of biopharmaceuticals, high-risk chemical processing, high-viscosity lithium battery slurry, and flammable and explosive products.

The explosion proof double planetary mixer adopted advanced technology, which is widely used in dispersing mixing middle or high viscosity flammable and explosive materials. PTFE-coated planetary mixers are particularly suited for processing high-viscosity, corrosive, high-purity, or temperature-sensitive materials, finding extensive applications in adhesive, pharmaceutical, chemical, and food industries. This equipment perfectly combines two major advantages.

Video Display

Product Parameter

|

Tank work volume |

10L |

|

Revolution speed |

0~48 rpm Adjustable |

|

Mixing rotary speed |

0~100 rpm Adjustable |

|

Scraper speed |

0~48 rpm Adjustable |

|

Dispersion speed |

2980 rpm Adjustable |

|

Vacuum degree |

- 0.09 Mpa |

Machine Features

Product Details

* PTFE coated double twist impeller / blade impeller

Planetary Mixer Structure

● Double Twist Mixing Head

● Double-layer high speed dispersing head

● Scraper

● Emulsifying head ( homogenizer head )

● The mixing head combination forms are tailored for different process. Twist impeller blade, Dispersing disc, Homogenizer and Scraper are optional.

Working Principle

Planetary power mixer is a kind of new high-efficiency mixing and stirring equipment with no dead spot. It features unique and novel stirrer mode, with two or three stirrers as well as one or two auto scrapers inside the vessel. While revolving around the axle of the vessel, the stirrers also rotate around its own axis at different speeds, to achieve complicated movement of strong shearing and kneading for materials inside the vessel. Besides, the scraper inside the equipment revolves around the axle of the vessel, scraping the materials adhering to the wall for mixing and achieving better effects.

The vessel adopts special sealing structure, capable of pressurized and vacuumized mixing, with excellent exhaust and bubble removal effects. Vessel jacket can be heating or cooling according customer's requirements. The equipment is sealed excellently. The vessel cover can be hydraulically lifted and lowered, and vessel can be moved freely for ease of operation. Furthermore, the stirrers and scraper can rise with the beam and fully detach from vessel body, for ease of cleaning.

Product Description

1. Lifting system: The electric or hydraulic lifting table drives the mixing tank to seal and move.With multiple mixing tanks, the recipe can be adjusted at any time, suitable for various laboratories and start-up companies.

2. PTFE Coating Spiral stirrer, Dispersion plate,Scraper,etc.: Based on 314 stainless steel, the agitator blades and dispersion discs are coated with polytetrafluoroethylene (PTFE) to achieve high wear resistance, non-stick properties, and excellent corrosion resistance.

3. Movable mixing tank with PTFE coating inside: Double handle design, customized discharge port direction, which the tank is easy to use.

The pot interior is coated with polytetrafluoroethylene (PTFE), perfectly complementing the stirring paddle to achieve outstanding properties of high wear resistance, non-stick material handling, and corrosion resistance.

4. Explosion-proof Control system - Buttons or PLC: Explosion-proof control box, ensuring high safety during equipment operation.There is a digital time relay, which can adjust the speed and working time of the mixer according to the process and characteristics of different products. emergency button. The electrical control cabinet integrates all the power on, off,control,voltage, current, and frequency conversion speed of the machine, and the mixing time setting is reasonably centralized,and the operation is clear at a glance.

5. Optional Hydraulic press machine: The hydraulic press is the supporting equipment of the planetary mixer or the powerful disperser. Its function is to discharge or separate the high-viscosity rubber produced by the mixer. For Laboratory Planetary Mixing Machines,The press equipment can be separate or integrated with mixing and pressing of the material.

Application

Product Specification

| Type | Design volume |

Working volume |

Tank inner size | Rotary power |

Revolution speed | Self-rotary speed | Disperser power | Disperser speed |

Lifing | Dimension |

| SXJ-0.5 | 1.13 | 0.5 | 130*85 | 0.4 | 0-70 | 0-150 | 0.75 | 0-6000 | Electric |

|

| SXJ-1 | 1.9 | 1 | 150*120 | 0.4 | 0-70 | 0-112 | 0.75 | 0-2980 | ||

| SXJ-2 | 3 | 2 | 180*120 | 0.75 | 0-51 | 0-112 | 0.75 | 0-2980 | 800*580*1200 | |

| SXJ-5 | 7.4 | 5 | 250*150 | 1.1 | 0-51 | 0-112 | 1.1 | 0-2980 | 1200*700*1800 | |

| SXJ-10 | 14 | 10 | 300*200 | 1.5 | 0-48 | 0-100 | 1.5 | 0-2980 | 1300*800*1800 | |

| SXJ-15 | 24 | 15 | 350*210 | 2.2 | 0-43 | 0-99 | 2.2 | 0-2980 | 1500*800*1900 | |

| SXJ-30 | 43 | 30 | 400*350 | 3 | 0-42 | 0-97 | 3 | 0-2980 | 1620*900*1910 | |

| SXJ-50 | 68 | 48 | 500*350 | 4 | 0-39 | 0-85 | 4 | 0-2100 | Hydraulic | |

| SXJ-60 | 90 | 60 | 550*380 | 5.5 | 0-37 | 0-75 | 5.5 | 0-2100 | 1800*1100*2450 | |

| SXJ-100 | 149 | 100 | 650*450 | 7.5 | 0-37 | 0-75 | 11 | 0-2100 | 2200*1300*2500 | |

| SXJ-200 | 268 | 200 | 750*600 | 15 | 0-30 | 0-61 | 22 | 0-1450 | 2400*1600*2800 | |

| SXJ-300 | 376 | 300 | 850*650 | 22 | 0-28 | 0-56 | 30 | 0-1450 | 3300*1300*3400 | |

| SXJ-500 | 650 | 500 | 1000*830 | 37 | 0-24 | 0-48 | 45 | 0-1450 | 3700*1500*3500 | |

| SXJ1000 | 1327 | 1000 | 1300*1000 | 45 | 0-20 | 0-36 | 55 | 0-1450 | 4200*1800*3780 | |

| SXJ2000 | 2300 | 2000 | 1500*1300 | 75 | 0-13 | 0-35 | 90 | 0-1450 | 4500*2010*4000 |