Bottle Filling Machine Manufacturers by MAXWELL

Product details of the bottle filling machine manufacturers

Product Description

Our bottle filling machine manufacturers varies from sizes, color and shapes. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea It satisfies all of the International quality standards, which are very strict. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea Wuxi MAXWELL Automation Technology Co., Ltd is superior to other companies in bottle filling machine manufacturers field in terms of scale, financial strength, R&D capability and management level. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

Product Introduce

Video Display

Machine Parameters

|

Model |

GSF-6 |

|

Filling range |

100-1000ml (Customizable) |

|

Filling speed |

20-35 bottles/min (Base on 100-500ml) (Also depend on filling material) |

|

Measurement accuracy |

±1% |

|

Power voltage |

2.5kw |

|

Working air pressure |

6-7kg/cm² |

|

Gas consumption |

0.7-0.9m³/min |

|

Dimention(L*W*H) |

2m*1m*2.2m |

|

Net weight |

650kg |

Features

● Adopts world-famous brands of electrical and pneumatic components, lowfailure rate, reliable performance, long service life.

● Material contact parts are made of stainless steel, easy to disassemble and assemble, easy to clean and meet the requirements of GMP.

● Easy to adjust filling volume and filling speed, operated and displayed by touch screen, beautiful appearance.

● With no bottle no filling function, liquid level automatic contral feeding.

● No need to change parts, you can quickly adjust the various specifications of the shape of the bottle.

● The filling head is equipped with a special leak-proof device. No wire drawingor drip leakage occurs during filling.

Machine Details

1. Anti-Foaming Filling Nozzle: With servo motor diving filling system to achieve the defoaming filling function, and anti-dripping with mechanical cutting and air blowing design to avoid dripping or leakage. This design enable the machine to fill thick, thin, easy foaming and many kinds of products.

2. High Precision Piston: Each stainless steel piston is polished from inside and outside, and 3mm thicker than regular piston. Such a workmanship will increase the cost, but the filling precision will become higher, service life longer, what's more less maintenance to do.

3. Diversified Air Cylinder Design: Latest cylinder design to achieve Staggered Filling Function, it makes the filling speed 1.5 times faster than traditional design. All air cylinder will be adopted with international brand, such as Festo, Air TAC.

4. Siemens PLC Touch Screen Smart Control: The filling speed and volume of each nozzle can be adjusted on the screen independently. For filling different products we can save the parameter in the screen as recipe, and one-button start when changing different packaging or products.

5. Servo Motor Control: Servo motor control makes the filling precision better, and diving filling system more smooth. Also it would be much more convenient to change filling volume and height of filling nozzle.

6. Electrical Cabinet: All the main parts of the machine will be adopted with international brand, such as Siemens, Schneider, Sick, Panasonic, etc. Long service life, easier to maintain and replace.

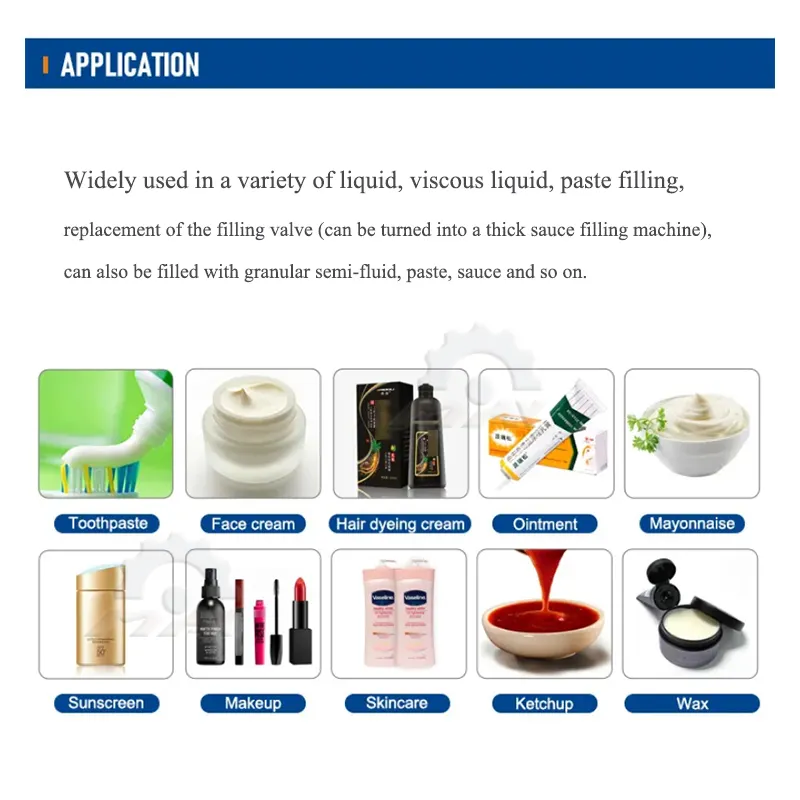

Application

Widely used in the filling of liquids, various liquids and pastes, replacement of filling valves ( that is multi-head thick sauce full-automatic filling machine), can also be filled with granular semi-fluid, paste, sauce.etc.

Company Advantage

• Our company has experienced and competent management team and various technical teams. Besides, we have a variety of advanced operating equipment. All this provides conditions for our product production and overall development.

• MAXWELL is located in a position where multi traffic lines pass through. It is conducive to outward transportation and the timely supply of cosmetic makingm machine,mayonnaise making machine,vacuum emulsifying mixer,double planetary mixer,filling machine,glue filling machine,silicone sealant filling machine,vacuum planetary mixer,industrial mixer,homogenizer,lab planetary mixer,vacuum homogenizer mixer,cosmetic cream mixer machine.

• Since the establishment in MAXWELL has always adhered to the development concept of 'integrity management, technological innovation'. Therefore, we put product quality and technological innovation in the first place. Based on the good reputation and quality products, we have won customers' support and love.

• Apart from the sales in major cities in China, our company's products are also exported to Southeast Asia, Europe, America, Europe and other countries and regions.

Have a hard time making choice among diverse products? Leave your contact information, and MAXWELL will send you the latest production information for comparison, so you could have a clear understanding.