Pet Bottle Filling Machine - - MAXWELL

Product details of the pet bottle filling machine

Product Overview

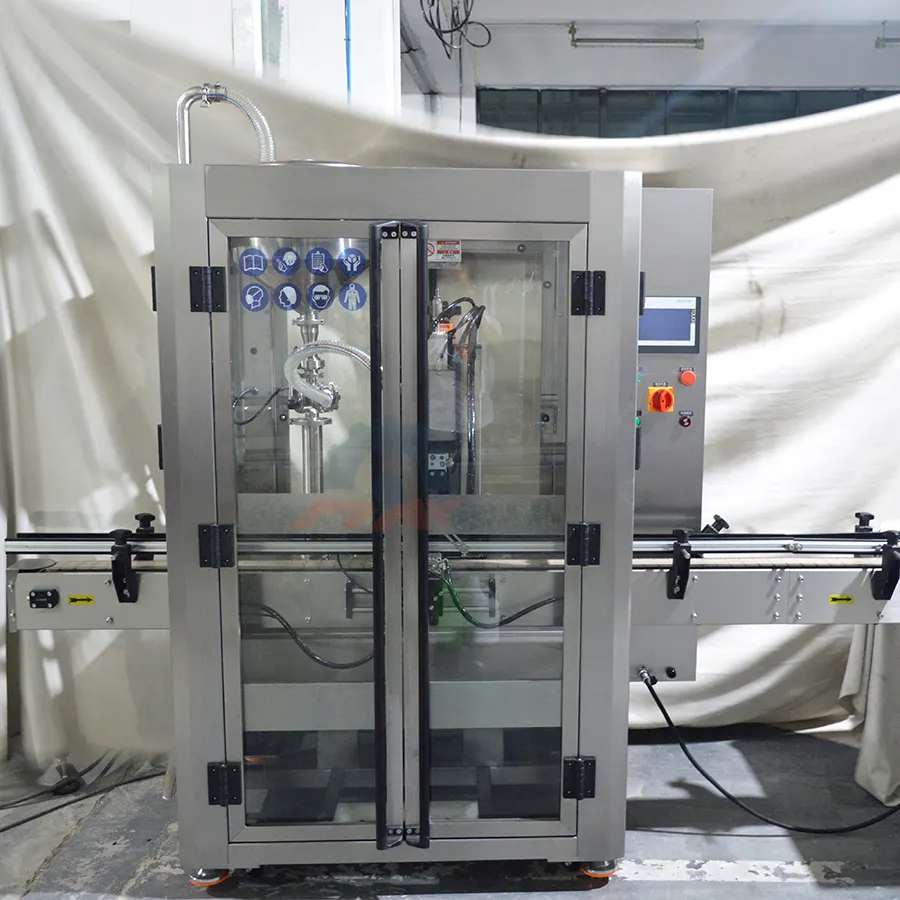

With the advantages of good material and smooth outline,pet bottle filling machine ocuppy the main market.Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea The product has been inspected in various aspects, such as surface imperfections, malfunction. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea MAXWELL's pet bottle filling machine can be applied to different fields and scenes, which enables us to meet different requirements. Wuxi MAXWELL Automation Technology Co., Ltd fully implements ISO9001:2000 quality management system. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

Product Introduction

pet bottle filling machine's details are presented below. They help better know the product.

Product Introduce

Video Display

Machine Parameters

|

Model |

GHS-1 |

|

Weight |

300kg |

|

Filling range |

50 ~ 1000ml |

|

Accuracy |

±1% |

|

Filling speed |

20 ~ 40 bottles/min ( Base on 100 ~ 500ml) |

|

Power |

0.8kw , 220V |

|

Working air pressure |

6 ~ 7 kg/cm2 |

|

Gas consumption |

0.5 ~ 0.7m3/min |

|

Certification |

CE |

Product Features

● Touch screen operation interface.

● Up and down movement type filling, effectively prevent the foam from being produced, easy to take apart and wash.

● The filling accuracy can reach +1%.

● The filling cylinder is ground, unique filling valve design, no leakage.

● No filling without bottle and automatic shutdown function for bottle accumulation.

● Design different positioning devices according to the actual situation of the bottle.

● The equipment is easy to clean and can be disassembled without tools. lt can also be cleaned online or sterilized at high temperature.

● PLC programmable control use Japan Mitsubishi.

● Frequency converter adopts France Schneider.

● Pneumatic components adopt Taiwan Airtac.

● Material contact parts are made of SUS304# stainless steel.

● The equipment meets the hygiene and safety standards. The user can choosethe glass protective cover.

Machine Details

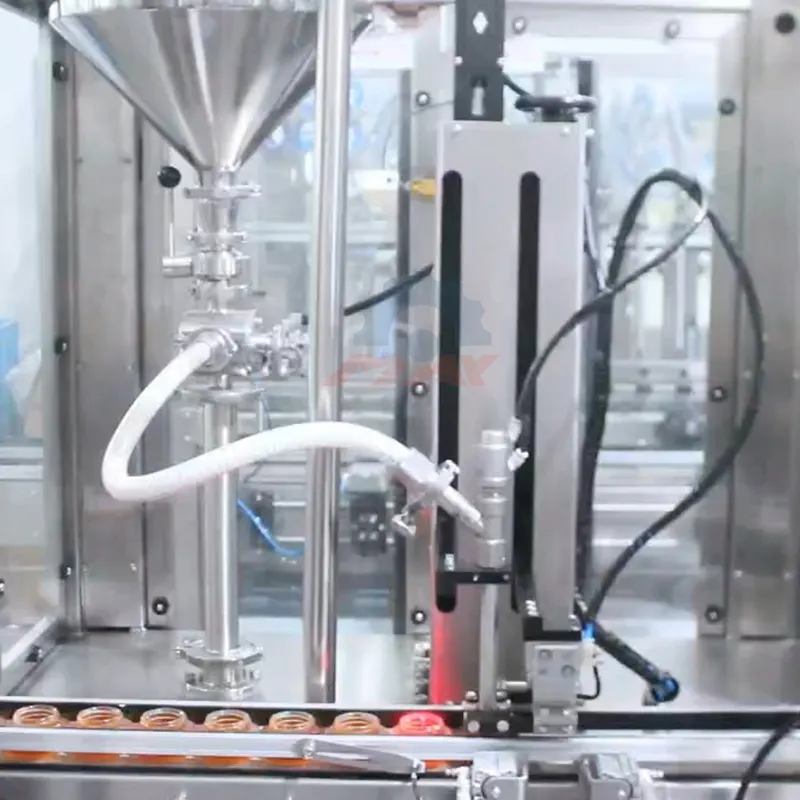

1. Anti-Foaming Filling Nozzle: With servo motor diving filling system to achieve the defoaming filling function, and anti-dripping with mechanical cutting and air blowing design to avoid dripping or leakage. This design enable the machine to fill thick, thin, easy foaming and many kinds of products.

2. High Precision Piston: Each stainless steel piston is polished from inside and outside, and 3mm thicker than regular piston. Such a workmanship will increase the cost, but the filling precision will become higher, service life longer, what's more less maintenance to do.

3. Diversified Air Cylinder Design: Latest cylinder design to achieve Staggered Filling Function, it makes the filling speed 1.5 times faster than traditional design. All air cylinder will be adopted with international brand, such as Festo, Air TAC.

4. Siemens PLC Touch Screen Smart Control: The filling speed and volume of each nozzle can be adjusted on the screen independently. For filling different products we can save the parameter in the screen as recipe, and one-button start when changing different packaging or products.

5. Servo Motor Control: Servo motor control makes the filling precision better, and diving filling system more smooth. Also it would be much more convenient to change filling volume and height of filling nozzle.

6. Electrical Cabinet: All the main parts of the machine will be adopted with international brand, such as Siemens, Schneider, Sick, Panasonic, etc. Long service life, easier to maintain and replace.

Application

Can be applied to food, pharmaceutical, daily chemical, pesticide, cosmetics and other industries of different bottle shape capping

Company Advantages

Wuxi MAXWELL Automation Technology Co., Ltd, located in wu xi, is a modern company in the industry. We run a major business of cosmetic makingm machine,mayonnaise making machine,vacuum emulsifying mixer,double planetary mixer,filling machine,glue filling machine,silicone sealant filling machine,vacuum planetary mixer,industrial mixer,homogenizer,lab planetary mixer,vacuum homogenizer mixer,cosmetic cream mixer machine. Based on the business philosophy of 'being honest and trustworthy, customer first, keeping pace with the times', our company carries forward the enterprise spirit of 'gratitude, dedication and devotion'. We take talent as the foundation, market as the guide and technology as methods to accelerate industrial upgrading. We also strive to build a first-class brand and become a well-known leader in the industry. MAXWELL has a powerful management team, an inexorable R&D team, a professional production team, and a strong sales team. This provides favorable conditions for company development. MAXWELL insists on providing customers with reasonable solutions according to their actual needs.

We have ample inventory and discounts for large purchases. Welcome to contact us!