Sealant Cartridge Filling Machine by MAXWELL

Company Advantages

· The strict control process ensures that MAXWELL sealant cartridge filling machine will meet the exact specifications. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

· This product enjoys long service time for its sophisticated quality. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

· What has been always attracting customers in MAXWELL is its good quality sealant cartridge filling machine and professional service. Wuxi MAXWELL Automation Technology Co., Ltd is a leading manufacturer of Industrial planetary mixers, vacuum emulsifying mixers, glue filling machines, capping machine and silicone sealant filling machines. MAXWELL has over 18 years of expertise and has developed immensely in the research, design, manufacture, sale, and service of different Mixing Machine and Filling Equipment used for various products such as lotions, creams, paste, sauces, gel, paints, epoxy resin, lithium battery slurry, grea

Product Introduce

Video Display

Product Parameter

|

Size |

3000mm×1550mm*1900mm |

|

Air Supply |

>0.5 MPa |

|

Filling Volume |

MAX 350ml Adjustable |

|

Volume Precision |

≤±0.5℅ |

|

Speed |

1200~2400pcs/hr |

|

Weight |

750kg |

Function

Product structure diagram

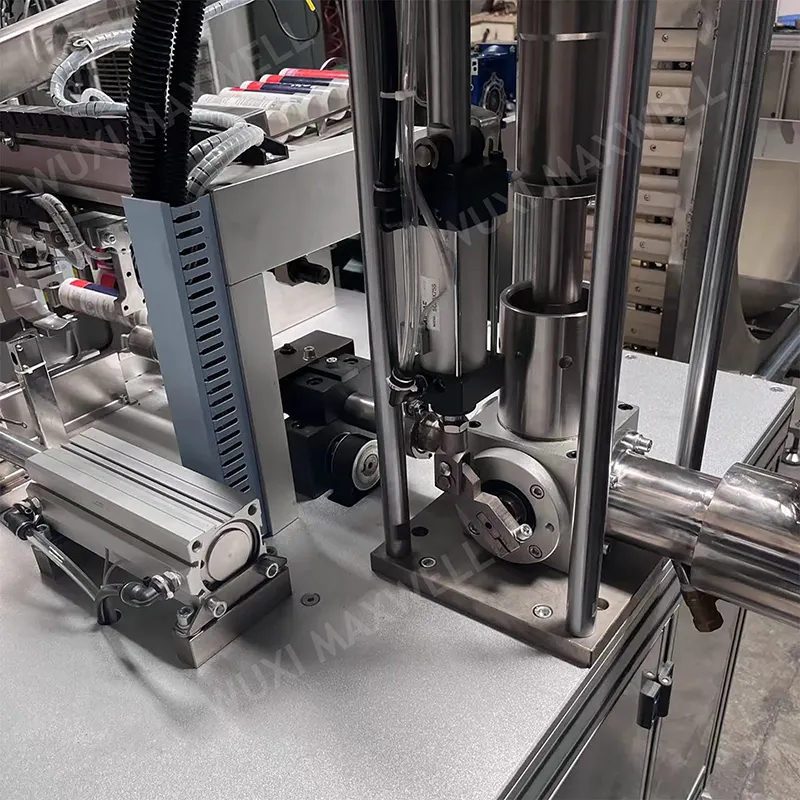

Machine Details

1. Filling & Capping system: Adopt volumetric measuring cylinder, servo motor control quantitative. Filling measurement accuracy is high (error 0.5%). No air comes in during the whole process.

2. Cartridge loading device: Adopt cartridge loader automatic loading the tube on machine. Silicone stations filling part connect with drum press and equip cartridge pushing and pulling function.

3. Cap loading device: Cap elevator and tunnel to auto load cap. Adopt vibrating bowl automatic loading cap. Air cylinder pushes cap on the tube bottom and then turn tube capping it.

4. Servo control system: Servo motor controlled filling, the whole work process is running stable.

Press Machine Parameter

|

Equipment name |

Press Material Machine |

|

Type |

YJ200-1/YJ200-2 |

|

Power Supply |

AC 3~380V+Nwire /50HZ |

|

Extrusion force |

45T/60T |

|

suitable bucket |

200L(Dia570MM*Heigh880MM) standard bucket |

|

Outlet size |

DN65 |

|

Hydraulic station oil tank |

120L |

|

motor |

4KW/Hydraulic motor |

|

Hydraulic station oil size |

L650MM*W550MM*H800MM |

Application

Company Features

· Wuxi MAXWELL Automation Technology Co., Ltd is immensely professional in manufacturing and supplying a full range of sealant cartridge filling machine.

· So far, our business scope has expanded to various countries. They are the Middle East, Japan, the USA, Canada, and so on. With such a wide marketing channel, our sales volumes have rocketed in recent years. Our factory has set up a strict production management system. This system includes inspection for the incoming raw materials, assembly and packaging requirements, and waste disposal requirements.

· We work closely with our suppliers to protect the future for our natural resources and ensure economic growth for neighboring communities.

Enterprise Advantages

With a focus on staff training, MAXWELL has an excellent team consisting of highly-educated and professional talents.

MAXWELL makes effort to provide quality and considerate services to meet the needs of customers.

MAXWELL always considers talent as one of the decisive factors for our sustainable development. Focusing on people and striving for common development are our corporate tenet. A talents team, created based on local, is the soul of the enterprise and also the motivation for rapid development.

MAXWELL was established in Our company receives unanimous praise from customers depending on years' industry experience, professional production technology, and perfect service system.

MAXWELL's cosmetic makingm machine,mayonnaise making machine,vacuum emulsifying mixer,double planetary mixer,filling machine,glue filling machine,silicone sealant filling machine,vacuum planetary mixer,industrial mixer,homogenizer,lab planetary mixer,vacuum homogenizer mixer,cosmetic cream mixer machine are supplied throughout the country. They are also exported to some countries and regions like